Newsletter | December 2020

On behalf of all of us at TeraView, I wanted to take this opportunity to send our best wishes for a safe end to 2020 to all of our customers, collaborators and to our friends throughout the wider terahertz community. We hope that you and your families are ending the year healthy and as well as can be in trying circumstances. We at TeraView have also lived through the challenges presented by COVID over the past year, and I am grateful for the tremendous hard work and effort of all of my colleagues at TeraView, who have strived to support the business and all of our customers as best they can over the last 12 months.

I also wanted to extend this thanks to all of our customers who have been tremendously patient and supportive of TeraView in spite of the trying times that they have gone through themselves. Your on-support has also been key to TeraView, and we will always be sincerely grateful for it.

TeraView ends 2020 in a strong position, having shipped and supported new terahertz systems to customers working in R&D, semiconductor and automotive paint inspection applications. We are also working with collaborators on exciting new applications in a range of areas which we hope to announce in 2021. That said, we fully recognise that strong support for our customers throughout the world is one of our core values, and that much more is now required as the prospect of travel becomes more realistic. At TeraView, we are firmly focussed on extending this support via direct visits as travel opens up again, and in the interim via on-line activities and other forms of customer assistance.

Our sincere wishes for a safer and successful 2021 to all of our customers, collaborators and the wider terahertz community throughout the world.

Dr Don Arnone, Chief Executive Officer and co-founder of TeraView.

TeraView News

Terahertz imaging aids in art restoration

TeraView is pleased to announce that it has begun a collaboration with the Russian Museum’s Technology Research Department in St Petersburg, Russia aimed at demonstrating the power and capabilities of terahertz imaging in art restoration.

TeraView is the leading supplier of terahertz systems to support a range of applications. Recently, the use of terahertz imaging in art restoration has been demonstrated by different museums and other institutions across the world.

In some paintings and other works of art, terahertz imaging is able to detect the sequence and thickness of the different layers of paint, each of which can be imaged separately, effectively producing a 3D image of the artwork. Terahertz imaging can thus help reveal the artist’s technique, as well as authenticate paintings in some instances where the identity of the artist is in question.

Additionally, terahertz imaging can assist art conservation and restoration decisions by providing information on cracks, delamination and defects buried below the surface and not visible to the naked eye or readily accessible with other techniques.

The full press release is available to view here.

Terahertz Coating thickness analysis

In this latest film, CEO Don Arnone gives an overview of the TeraCota sensor.

Designed for the coatings industry, the TeraCota sensor can determine the individual thickness of multiple paint layers on both metallic and non-metallic substrates and offers significant benefits over existing techniques.

The sensor is non-contact, suitable for working on curved surfaces and capable of performing horizontal and vertical line scans.

For more information on the TeraCota system see this page.

Calmar Laser

TeraView’s TeraPulse Lx system now contains Calmar Laser’s high powered Mendocino fiber laser module.

With over 25 years of experience, Calmar’s world-leading ultrafast fiber laser solutions ensure reliable and robust integration into TeraView’s systems.

For more information contact TeraView or Calmar Laser directly.

Podcasts

TeraView CEO Don Arnone discusses terahertz light, what it is and why it’s important, its various industrial applications, and how TeraView has managed to commercialise a new area of fundamental science. Hosted by Turquoise.

Select Papers

Terahertz-Based Porosity Measurement of Pharmaceutical Tablets: a Tutorial

Bawuah, Prince, Daniel Markl, Daniel Farrell, Mike Evans, Alessia Portieri, Andrew Anderson, Daniel Goodwin, Ralph Lucas, and J. Axel Zeitler. “Terahertz-based porosity measurement of pharmaceutical tablets: a tutorial.” Journal of Infrared, Millimeter, and Terahertz Waves (2020): 1-20.

Abstract

Full article available here.

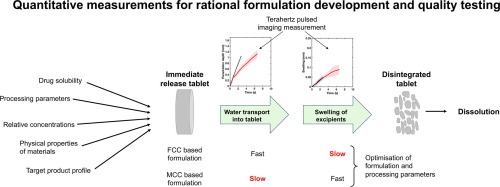

Simultaneous Investigation of the Liquid Transport and Swelling Performance during Tablet Disintegration

Al-Sharabi, Mohammed, Daniel Markl, Theona Mudley, Prince Bawuah, Anssi-Pekka Karttunen, Cathy Ridgway, Patrick Gane et al. “Simultaneous Investigation of the Liquid Transport and Swelling Performance during Tablet Disintegration.” International Journal of Pharmaceutics (2020): 119380.

Abstract

Full article available here.

Would you like to partake in an online workshop?

TeraView are looking at conducting online workshops in 2021

Contact us if you are interested