TeraCota – Terahertz Coating thickness analysis

A Non-Contact, Multi-Layer Coating & Paint Thickness Sensor with Scanning Capability.

TeraView presents a film thickness gauge designed for the automotive industry.

TeraView presents a film thickness gauge designed for the automotive industry.

The sensor can determine the individual thickness of multiple paint layers on both metallic and non-metallic substrates and offers significant benefits over existing techniques.

The terahertz sensor is non-contact, suitable for working on curved surfaces and capable of performing horizontal and vertical line scans.

Based on terahertz technology, the sensor represents a significant leap beyond the current method of measurement for quality and process control in automotive paint application, and also provides significant economic and environmental benefits.

Unit Sensor

Production Features

- Non-contact – no couplant required; operates on flat and curved surfaces, including windshield flanges.

- High accuracy reporting of film thickness.

- Single and dual sensor options.

- Self-calibrating without the expense and time of sending samples to a third party.

- Suitable for wet-on-wet preparations.

- Industrialized form factor; designed for the automotive manufacturing environment.

- Can be integrated with plant IT systems and existing robotic hardware.

- Non-interpretive; automatic layer thickness calculation without operator input.

- Optional vehicle position measurement unit to correct for body position repeatability errors.

Application Areas

Paint Systems

| Application Types | Liquid and powder coatings | wet-on-wet preparations | tri-coats |

| Basecoats | Solid | Pearlescent | Metallic (independent of hiding power) |

| Substrates | Metallic (steel, aluminium, etc.) | non-metallic (plastic, carbon fibre, etc.) |

Measurable Surfaces

| Curvature | Operates on both flat and curved surfaces |

| Accessible areas | Recessed areas, including window flange |

| Temperature range | From ambient to 150 °C (post bake) |

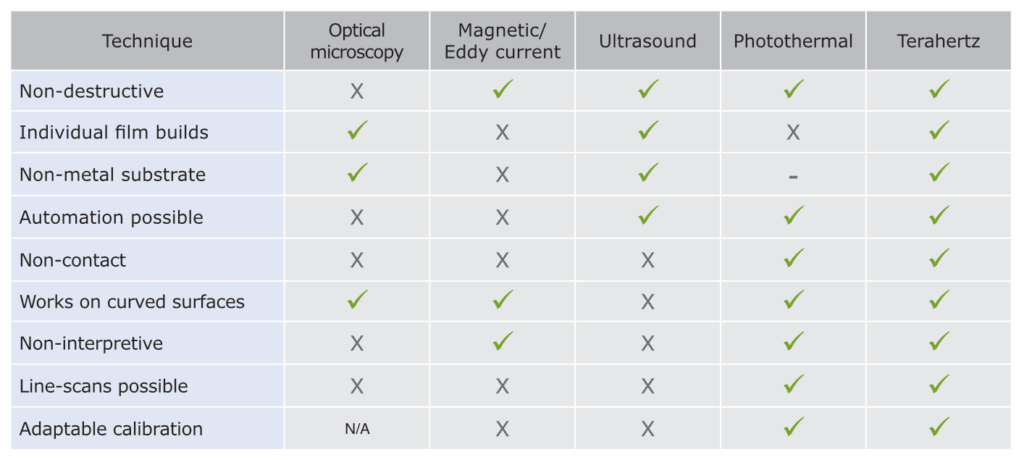

Comparison Table

Technical Specification

Measurement

| Thickness Accuracy* | 1.5 µm |

| Minimum Thickness* | 5 µm |

| Sampled Area | Spot diameter of approximately 2 mm |

| Measurement Time | Typically 4 seconds per point (excluding alignment) |

| Sensor Positioning | Working distance to painted surface of 88 mm (± 0.15 mm) |

| Robot-mounted version requires angular positioning to within ±0.2° of normal incidence |

* typical values; dependent on individual paint type and properties

Environmental

| Dimensions (L×W×H) | Sensor head: 11.5 × 8.8 × 11.3 cm | Core unit: 59 × 55 × 77 cm |

| Rack mount modules | Optics Rack Assembly 4U, Electronics Rack assembly 3U, Processing PC 3U |

| Approx. weight | Sensor head: 1.4 kg | Core unit: 82 kg |

| Extension | Sensor-core separation of up to 15 m |

| Communications | Ethernet connection to fixed IP address on internal PC |

| Power requirements | 110 / 220 V, 20 A line power, earthed, via standard 3-pin connection |

| Operating temperature | 18 °C (64 °F) – 30 °C (86 °F) |

| Operating humidity | 20 – 80%, non-condensing |