Battery Production

Key benefits:

-

The TeraCota sensor uniquely measures coating thickness, density and loading.

-

Optimise the manufacturing process for electrode coatings (cathode & anode).

-

All in one non-contact measurement in real-time.

-

Improve and optimise capacity.

-

Eliminate waste & scrapped cells.

-

Reduce and control manufacturing costs.

-

Ensure uniformity of electrode coating.

The battery manufacturing industry is one of the fastest growing production industries, with annual global lithium-ion battery capacity demand increasing to > 1000 GWh cell energy in 2030, triggering expected investments of more than $150 billion.

Losses in the manufacturing of lithium-ion batteries due to scrappage of out-of-specification cells can be as much as 30%, with even higher numbers possible at the ramp-up of new manufacturing runs.

This wastage contributes overall battery cost, and becomes very significant as production is scaled up in giga factories.

As Terahertz techniques are non-contact then there is no need for a coupling fluid, typically water for ultrasound techniques, which is both environmentally friendly and allows for additional measurements such as colour finish to be evaluated in the same cell.

The ability to rapidly monitor coating thickness, density, loading and conductivity in the production of electrode coatings and provide real-time feedback for process control is an important contributor towards eliminating wastage costs and ensuring supply to market without production stoppage.

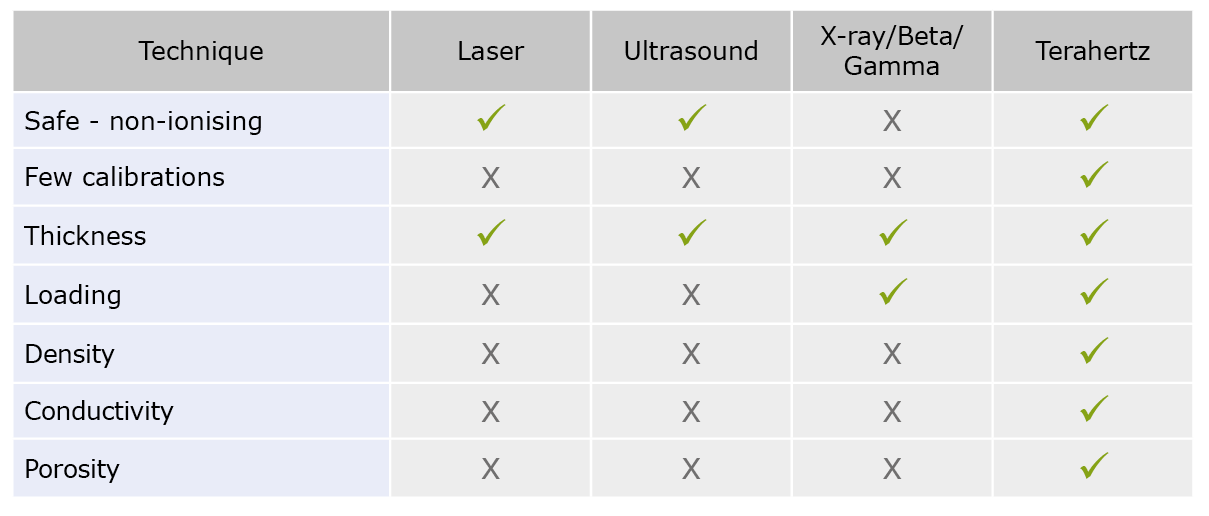

The measurement technique for electrodes is an established field with multiple techniques for monitoring each parameter. Previously, no single device could measure all the key parameters in real-time.

Off-line techniques such as sampling and testing are also used. However, on large scale production, the off-line trial-and-error approach can lead to much additional wastage and equipment downtime.

In-line measurements also offer the opportunity for real-time process control as noted above, with cost reduction and insurance-of-supply benefits.

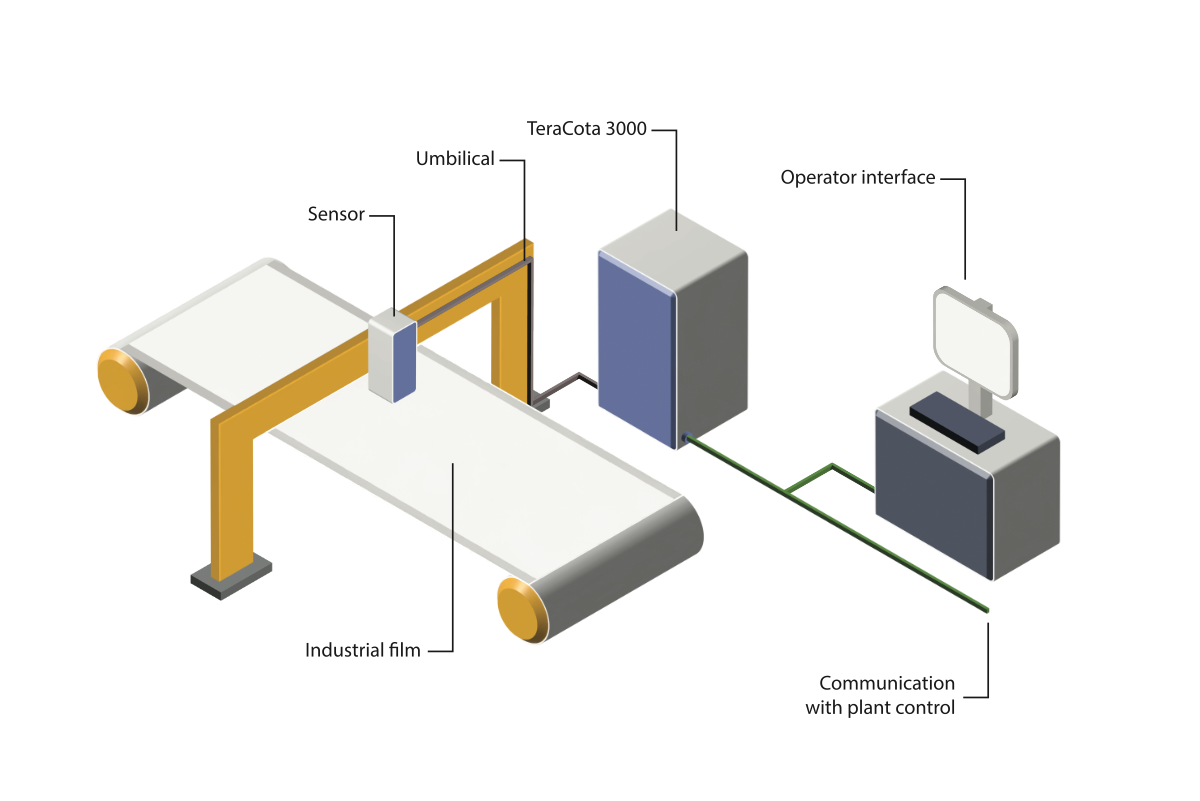

TeraView’s implementation of Terahertz technology (TeraCota), is a single non-contact sensor that measures all key parameters in real time in production.

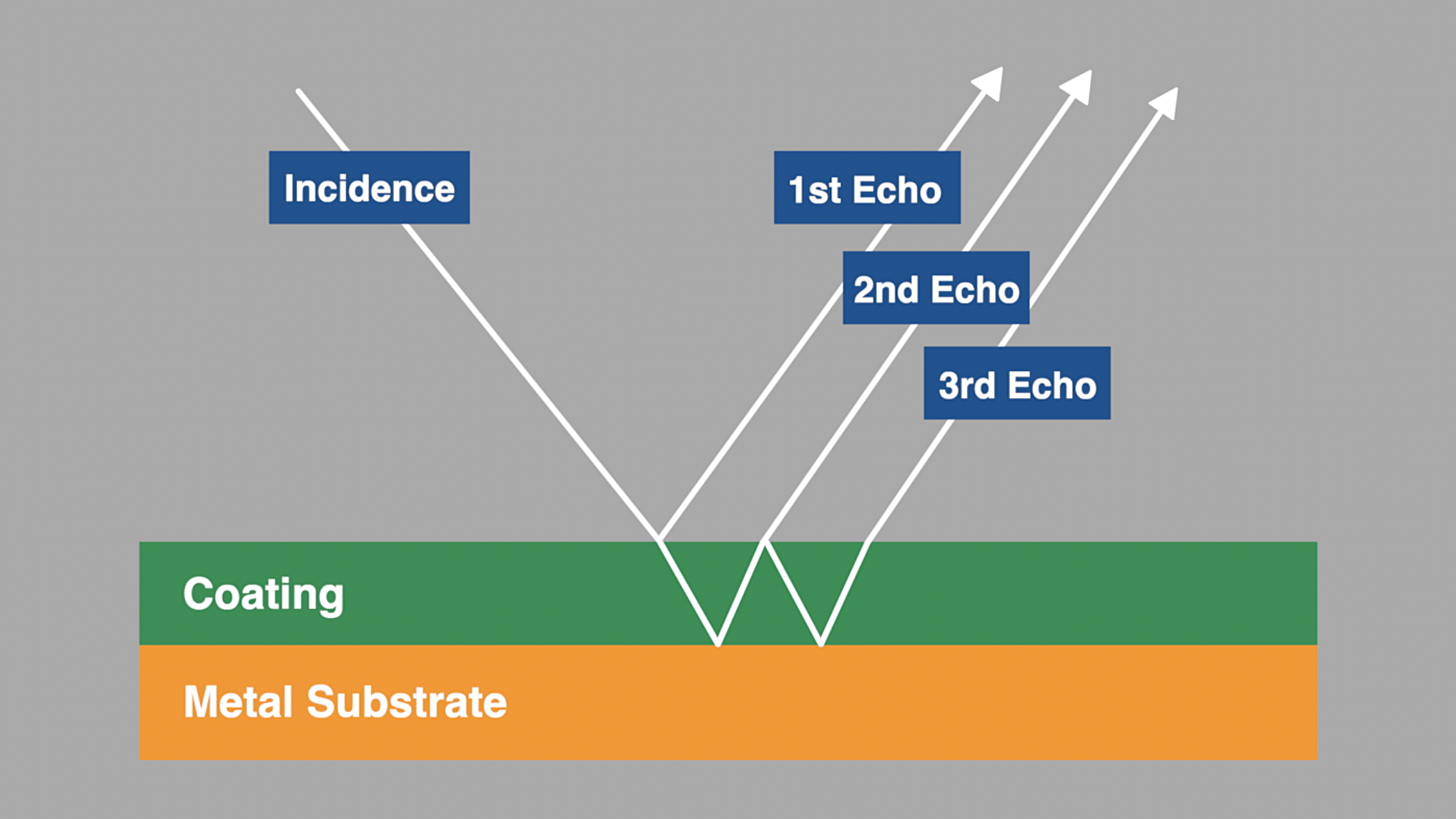

The Terahertz technique uses highly accurate time of flight measurements to determine electrode thickness based on multiple reflections of Terahertz pulses from different coating interfaces.

Additionally the solution works equally well for anodes and cathodes, and is applicable to dry or wet electrodes.

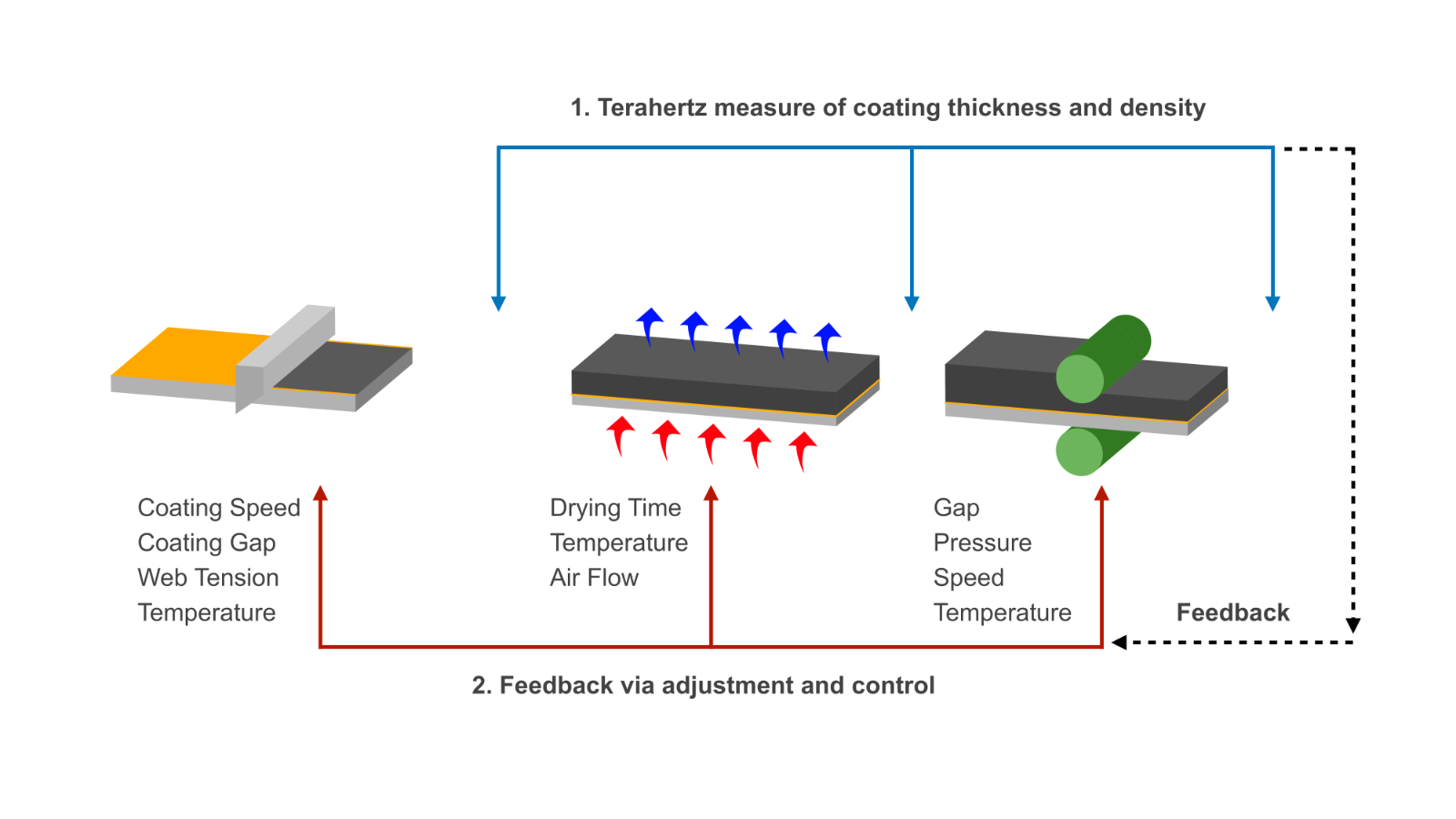

There are a number of stages in the production process where Terahertz sensors can interface to the process control and reduce waste; see Figure 6 below.

An optimum in-line configuration would measure coating parameters and feedback these to control the coating speed, gap, drying etc.

The solution also works for both calendared and uncalendared electrodes.

A typical system has a sensor head that is mounted on a gantry that traverses the electrode during production. The traversing speed of the gantry is programmable to optimise the manufacturing needs. The head connects to the control cabinet via a flexible optical cable which is embedded within the energy chain of the gantry mechanism. The system PC translates the measured waveforms into the key parameters and displays these for operator usage.

- Suitable for both anodes & cathodes

- Measures dry & wet electrodes

- Multiple electrode types tested : LFP, NMC, LTO, LMO

- +/- 1µm accuracy

- Web width up to 2m possible

- Double or Single sided electrodes