Newsletter | July 2022

TeraView launch a new product to address the growing needs in advanced IC packaging

TeraView is pleased to announce the launch of the purpose-built integrated circuit package inspection system, the EOTPR 4500.

Dr Jesse Alton, Semiconductor Product and Applications Manager at TeraView commented “The key feature of the EOTPR 4500 is the auto prober technology we developed to meet the challenges of the most advanced IC packaging technology by accommodating the substrate size of up to 150mm x 150mm while improving the probe tip placement accuracy to +/- 0.5 µm. The new auto prober enables our customers to probe very large chip-let devices with the landing contact size of less than 5 µm such as copper pillars and TSV tips. We closely collaborated with a major advanced packaging customer to develop this product, and the product has completed a rigorous beta site testing period at this customer site to ensure that the new product is production ready.”

Martin Igarashi, TeraView’s VP of Semiconductor Business, commented “We have realized most of the probe stations are inadequate to meet the demand of the IC packaging probing which is quite different from the wafer probing since wafer surfaces are completely flat. What this means is that the wafer based probe stations can crush or stress the probing points such as TSVs, or they need to land the probe tip painfully slow to avoid introducing artefacts into the target sample. This product enables our customers to isolate faults in their most advanced IC packaging devices while taking advantage of EOTPR’s industry leading sub-5 µm distance-to-defect capability. It also offers a device under test (DUT) heater that goes up to 250 °C, which means a customer who are working on advanced graphics engines or autonomous driving AI engines can now isolate faults on their devices while simulating the working conditions of these devices.”

Dr Don Arnone, TeraView’s CEO, commented “This is another first from TeraView to introduce a product that is purpose built for very demanding advanced IC packaging market. We are pleased to have a close collaboration with a major customer to develop this product, and we are quite confident that this product will set a new standard in advanced IC packaging failure analysis. Combined with TeraView’s TeraCota automotive paint thickness inspection system, TeraView can address the growing needs of the automotive IC industry with this product.”

New Members of Our Team

Deepesh Patel (left) joins TeraView’s Semiconductor Group (pictured with Dr Jesse Alton & Dr Tom White). Andy Bell (right) joins as VP Business Development for Automotive & High Value Coatings.

Andy Bell recently joined TeraView as VP Business Development for the Automotive & High Value Coatings business. Prior to this he was at Rockwell Automation for 23 years, having held several senior positions. Andy brings a depth of global experience to the role of Industry applications and addressing customer needs.

Deepesh Patel has joined TeraView as part of our Semiconductor Group, and will be assisting with EOTPR development and support. We welcome both on board!

Calmar Laser

TeraView’s TeraPulse Lx system now contains Calmar Laser’s high powered Mendocino fiber laser module.

With over 25 years of experience, Calmar’s world-leading ultrafast fiber laser solutions ensure reliable and robust integration into TeraView’s systems.

For more information contact TeraView or Calmar Laser directly.

Select Papers

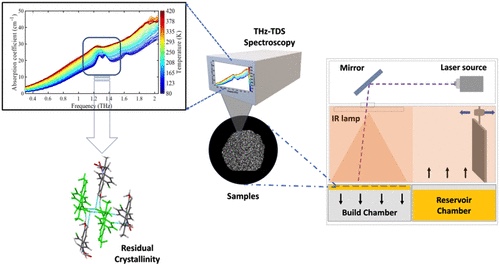

Detecting Crystallinity Using Terahertz Spectroscopy in 3D Printed Amorphous Solid Dispersions

Abstract

Terahertz Dielectric Characterization of Low-Loss Thermoplastics for 6G Applications

Abstract

Previous Events & Conferences

Europe

TeraView attended the Battery Show Europe in June as part of our developments into the Battery Industry. Many quality customer discussions were held and as a result we will exhibiting at future events both in USA (September ’22) and Europe (May ’23).

The Battery Industry remains a focus for TeraView, with our innovative solutions that allow us to measure Thickness, Density & Conductivity for both Cathode and Anode electrodes.

United Kingdom

TeraView were proud to participate and present at the Innovate UK “Celebration of the UK Battery Innovation Ecosystem” on 15th July in London. Many companies met and shared information on active innovations to grow the Battery Industry in UK.

Upcoming Events & Conferences

TeraView will be exhibiting at IRMMW-THz 2022, to be held in the Netherlands between 28 August and the 2nd September, we will be on-hand to discuss all aspects of terahertz, visit us at booth 4.

Further information can be found on the event website here.

Would you like to partake in an online workshop?

TeraView are looking at conducting online workshops throughout the year.

Contact us if you are interested